Dial in tooling performance like never before.

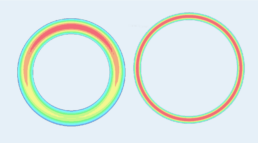

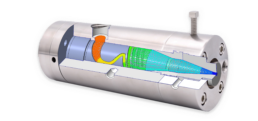

Start with B&H Flow Analytics™

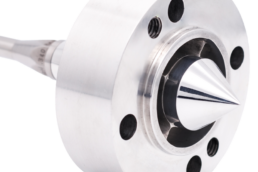

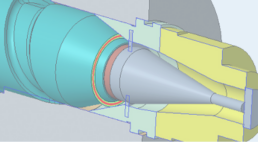

B&H Tool specializes in performance-driven extrusion tooling using advanced

Flow Analytics and simulation models to improve tool design and performance. MORE

See what optimized output looks like.

Leading companies look to B&H Tool for expert design and optimized

standard and custom engineered extrusion tooling products.